New and improved technical tools Imaging lens selector Visit

Product classification

GCG-600-1.0-25 Plane Diffraction Grating

GCG-Plane Diffraction Grating

Grating is a common optical dispersion component. It is an object or device that has a spatial periodic distribution within a certain spatial range and can amplitude modulation or (and) position phase modulation of electromagnetic waves according to certain laws. According to the usage, the grating can be divided into transmission gratings and reflection gratings, and reflective gratings can be divided into plane reflection gratings, concave reflective gratings, echelle gratings, etc.

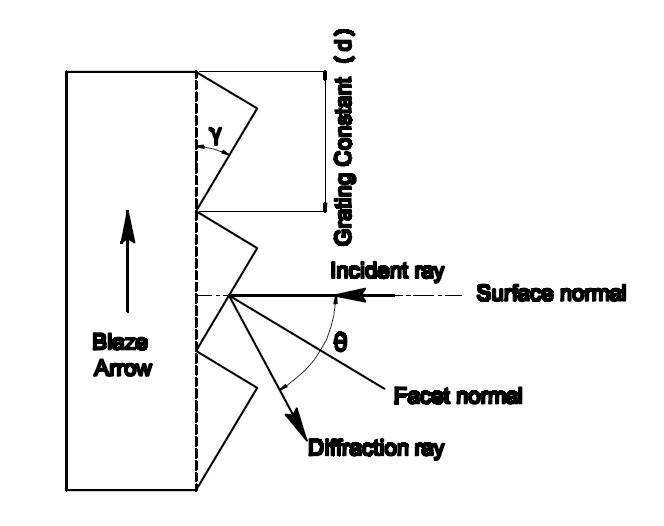

GCG series grating is one of the plane reflective gratings, which is characterized by the maximum diffraction light intensity-level glare falling outside the zero-stage spectrum, so it is called the blazed grating. For serrated grooves, the direction with the greatest light intensity is the direction of the groove surface determined by the law of reflection.

Daheng Optics provides a blazed grating with a lithography of 300-1200 lines within a range of 360nm-1250nm. At the blazed wavelength, the grating diffraction efficiency can reach 60% to 80%. It has two dimensions of 12.5mmx12.5mm and 25mmx25mm. The back of the grating is polished, and the side is marked with an arrow indicating the direction of the grating, as shown in the schematic diagram below. The damage threshold of this series of gratings is typically tested at 532nm, about 150mJ/cm2 (532nm, 10ns, 10Hz). Please note not to exceed the laser threshold during use.

The surface of the grating is engraved with precision grooves, which is very vulnerable to damage. Please place it in a clean and dry environment. Don't touch or wipe the surface of the grating when using it. When cleaning, only clean and dry air can be used.

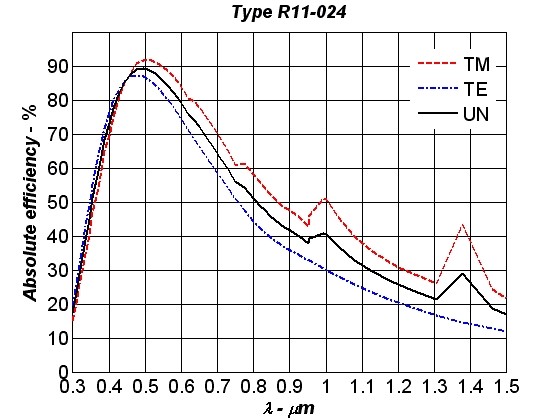

Curve of Grating

GCG-Plane Diffraction Grating

|

Part No. |

Line |

Blazed Wavelength(um) |

Blazed Angle |

Dimension |

Tolerance |

Thickness |

Tolerance |

Surface Quality on back |

Damage Threshold (532nm,10ns,10Hz) |

|

300 |

0.5 |

4.3º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

300 |

0.5 |

4.3º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

300 |

1 |

8.6º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

300 |

1 |

8.6º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

0.36 |

6.2º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

0.5 |

8.6º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

0.5 |

8.6º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

0.72 |

12.5º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

0.72 |

12.5º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

1 |

17.5º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

1 |

17.5º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

1.25 |

22.0º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

1.25 |

22.0º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

1.6 |

28.7º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

600 |

1.6 |

28.7º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

1200 |

0.36 |

12.5º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

1200 |

0.5 |

17.5º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

1200 |

0.5 |

17.5º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

1200 |

0.72 |

25.6º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

1200 |

0.72 |

25.6º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

1200 |

1 |

36.9º |

12.5x12.5 |

0,-0.05 |

4 |

0,-0.05 |

Polished |

150mJ/cm2 |

|

|

1200 |

1 |

36.9º |

25x25 |

0,-0.05 |

6 |

0,-0.05 |

Polished |

150mJ/cm2 |

© 2019 Daheng New Epoch Technology,Inc. 京ICP备05081235号-2